The Air-Cooled dehumidifiers with desiccant Rotor are used for drying air of up to 95% relative humidity (RH) with temperatures -20ºC to +45ºC. It is widely used in the area of Far East Asia, West Europe, North America with temperate climate.

The applications are numerous and wide spread. Below are some examples:

- Surface treatment during internal blasting and painting of tanks

- Shipping industry, both for permanent and temporary applications

- Controlling humidity levels in production processes

- Protection of equipment sensitive to corrosion

- Climatic improvements in damp areas

Air Cooled Dehumidifier with desiccant rotor is delivered as a complete unit with fans, filters, condenser, evaporator, compressor, DESICCANT ROTOR, REGENERATING HEATING and controls. The dehumidifier is ready for site installation and connection to standard-size ducting. Each dehumidifier will be custom designed according to the local conditions and the needs of the customer.

|

Air Cooled Dehumidifier With Desiccant Rotor for All Climate |

||||

|

Model |

KL-LFD6000 |

KL-LFD9000 |

KL-LFD12000 |

KL-LFD18000 |

|

Process Airflow (m3/hr) |

6000 |

9000 |

12000 |

18000 |

|

Compressor Power (kw) |

30 |

45 |

60 |

90 |

|

Process Air Fan (kw) |

7.5 |

11 |

15 |

22 |

|

Reheating Power (kw) |

50 |

75 |

100 |

150 |

|

Regenerating Heating Power (kw) |

36 |

54 |

72 |

108 |

|

Desiccant Rotor (mm) |

Φ550×200 |

Φ770×200 |

Φ965×200 |

Φ1220×200 |

|

Outlet connection (mm) |

Φ250×2 |

Φ250×3 |

Φ250×4 |

Φ300×6 |

|

Total Power (kw) |

133 |

195 |

260 |

395 |

|

Equipment Size (mm) |

≤ 4100×2000 ×2450 |

≤ 4500×2200 ×2500 |

≤ 4850×2200 ×2700 |

≤ 5800×2300 ×2800 |

|

Weight (t) |

3.6 |

4.2 |

4.9 |

7.9 |

|

Machine Structure |

Movable Containerized |

|||

|

Temperature Control Type |

High sensitive temperature sensor + PLC auto control + Touch Screen Display |

|||

|

Condenser |

Copper Tube + Aluminium Fins with galvanized casing |

|||

|

Evaporator |

Copper Tube + Aluminium Fins with galvanized casing Copper Tube + Copper Fins with stainless steel casing |

|||

|

Air Intake Condition |

Temperature: -10~40°C, RH≤95% |

|||

|

Air Discharge Condition |

Temperature: 25±3°C, RH≤45% |

|||

|

Air Discharge Pressure |

≥ 1800Pa |

|||

|

Electrical Control |

100% refrigeration / 100% Desiccant Rotor / Refrigeration + Desiccant Rotor /100% Heating |

|||

1. Power supply: 3-phase plus earth 380V/ 415V / 50 Hz

2. Refrigerant: R22, OTHER REFRIGERANT FOR OPTIONAL SUCH AS R134A

3. Cooling step control: 25%~50%~75%~100%

4. Cooling Media: Air

5. Discharge condition: 25 ± 3 °C/RH below 45%

6. We have the policy to improve our equipment continuously & shall reserve the rights to change the dimensions and specs without prior notice.

|

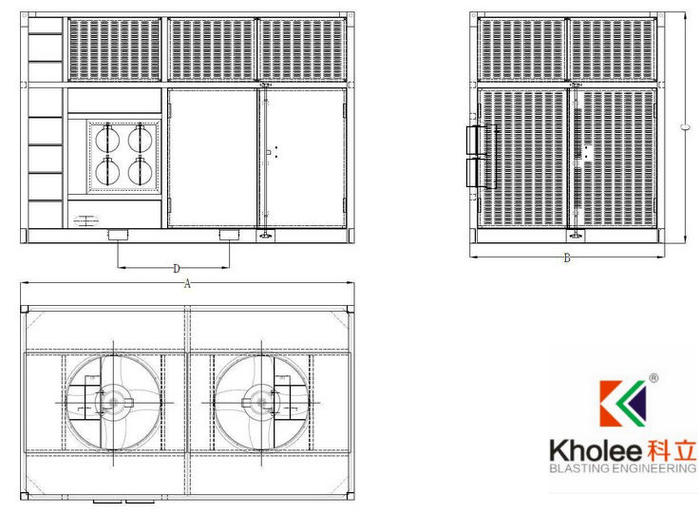

DIMENSION OF AIR COOLED DEHUMIDIFIER WITH DESICCANT ROTOR |

||||

|

Model |

KL-LFD6000 |

KL-LFD9000 |

KL-LFD12000 |

KL-LFD18000 |

|

LENGTH A (MM) |

4100 |

4500 |

4850 |

5800 |

|

WIDTH B (MM) |

2000 |

2200 |

2200 |

2300 |

|

HEIGHT C (MM) |

2450 |

2500 |

2700 |

2800 |

|

FORKLIFT D (MM) |

1400 |

1400 |

1400 |

1400 |

Contact:Carl Chen

Phone: +86-139 1469 8671

Email:kholeeblasting@gmail.com

Add:Dalong Industrial Park, Xituan, Dafeng, Yancheng, Jiangsu, China 224125

We chat